Importance of Process Optimisation at Animal Feed Mills

VDS Premix makes it a point of honour to support our customers, even inside their actual feed plant. In addition to creating custom premixes and additives, we are happy to pay you a visit if needed to determine what improvements are possible and how we can adapt the production process to achieve optimal results together. Minor tweaks to machine settings or ingredients may vastly improve the physical quality of the feed. VDS Premix has previously helped out customers all around the world and is currently advising on production and management in various countries in Africa, the Middle East and Asia.

Less downtime for more efficient production

Time is money, especially when it comes to production. Every second of downtime is a lost opportunity. When our consultants are asked to optimise a feed mill, the production line’s uptime is the first thing we work to improve. We take preventive action by performing timely repairs, sourcing the required parts through our extensive industry network.

Better ingredients, stricter quality control

We can say with confidence that VDS Premix is especially good at selecting the best ingredients for optimal nutrition. Our experts research available ingredients and prices on-site. Depending on the animals’ stage of life and genetic properties, we can design modifications to optimise the nutrient value and consequently, your yield as well.

Thorough quality control of the end product is another essential component in (preventive) process optimisation. We grant careful attention to every element of the production process; from ingredients, storage, recipe and quality control to monitoring of the production process, maintenance and storage and sales of the end product. Wherever we can, we make changes to improve the final product’s physical and nutritional characteristics. If feasible, we also establish protocols for continued remote monitoring of the product quality and process.

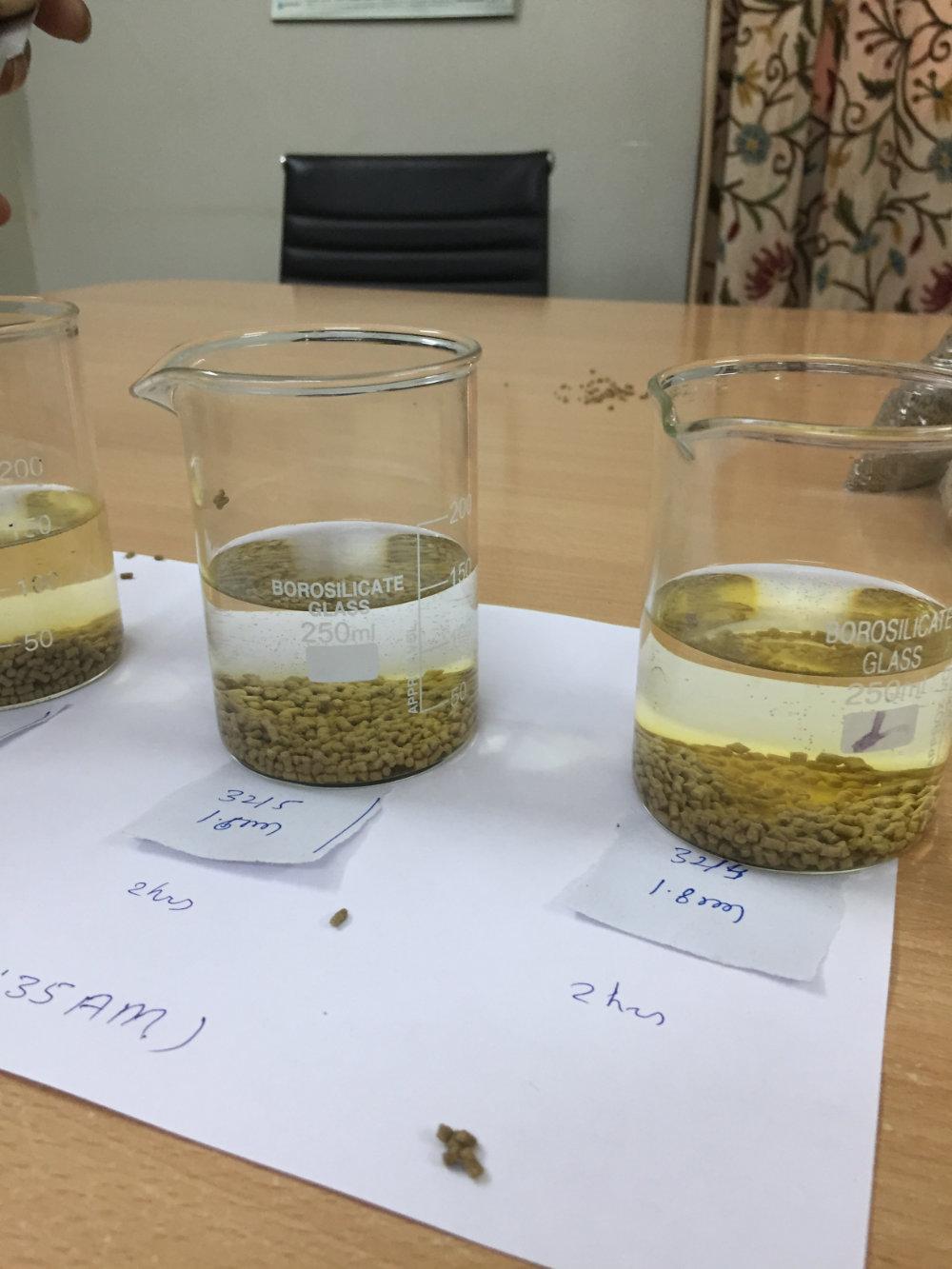

Process optimisation from India to Madagascar and the Seychelles

We’d like to provide a few examples to illustrate how this works in practice. These were also highly international collaborations, an area where we feel very much in our element. At the Abis feed plant in India, we began by optimising the feed physically. Then we moved on to nutritional recommendations and improvements to the production process. The results? Abis is now producing and selling 300% more than it was five years ago.

VDS also believed in the potential of Antsirabe, located in Madagascar. We sent over a management team and helped them set up a new shrimp feed production line. This can now be produced locally, eliminating the need for imported feed. Finally, we put our powers to work supporting a shrimp feed factory in the Seychelles in launching its export activities. At its peak, the factory was running day and night, supplying 6000 tonnes of feed annually to shrimp farms in neighbouring countries.